-

Posts

3,255 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Posts posted by James H

-

-

2 hours ago, Grunhertz said:

To be honest Jim the photos look fine, the problem is every troll in the world is lining up to have a pop at this kit. I don't know why I suspect that every thing changed because of the WNW kit but it's not out and this is. So let's enjoy it

Remember, everybody is an expert

2 hours ago, HubertB said:

2 hours ago, HubertB said:Will follow this one with interest.

As for the comments on another forum, it is fascinating to watch mob phenomena. Since the annoucement of the WnW release in one year (or more) from now, comments about the HK kit have evolved from enthusiasm to bad-faith trashing. I suppose it is human nature to judge comparatively (and in this case, the comparison is between real stuff vs 3D renderings) rather than in absolute terms the merits of products

.

.

Anyway, from your review pics and considering your talent, I am sure your end result will be outstanding

Hubert

Your faith in my ability is welcome! Thank you.

You are right with your comments on the phenomena. Another day at the plastic modelling criticism coalface.

1 hour ago, Maxim said:

1 hour ago, Maxim said:Interesting that the majority of those people that trash a kit before it's even released are often people that are arm chair experts and never build nothing. Both the HKM Lancaster and the WNW Lancaster appeal to different modellers. I think the WNW kit when released will give many people sticker shock. I can just hear those experts whining about the price. The HKM kit will give many modellers the chance to have a Lancaster in their collection who can not afford the WNW Lancaster. Both kits tailor to different modellers. The HKM kit is a nice accurate Lancaster out of the box. The WNW Lancaster comes with all the bells and whistles. We never had it so good.

We certainly haven't had it so good. Couldn't agree more!

I'm really enjoying this build and looking at making my own little marks where I can. The aim is to show the kit in the best light that I possibly can, as is the same with anything I try my hand at.36 minutes ago, Wingco57 said:Nice touch James. That panel covers the wiring loom to prevent damage.

Cees

Dank je!

-

5

5

-

-

-

Lancaster B Mk.I, R5868, PO-S (S-Sugar)

It's been a week or so since I tool delivery of the test shot for HK's soon-to-be-released Lancaster kit, and despite some pretty crap illness last week, I made some headway this weekend and snipped some plastic. Most of what you see here is dry-fit, with a very small number of glued components. I've read on another site that this model has soft detail and soft edges. Perhaps that's the impression my photos gave, but actually having the plastic here, I know it's not the case, and is no better/worse than recent and contemporary releases, and is every bit as sharp as I would expect from a modern tooling. There was also a hint towards 'brand loyalty' too, suggesting that I would happily write nice words where none were really justified (in not as many words). My answer to that is bullshit. There's no such thing as a perfect kit, and this is far from a perfect kit. However, the Lanc is my thing, so here we go.

From the RAF Museum:

QuoteBuilt by Metropolitan-Vickers at its Mosley Road works, Manchester. After completion taken by road to A.V.Roe plant at Woodford. Part of a batch of 100 originally ordered as Manchesters in 1939 of which only the first 43 were built as such, the remaining 57, including R5868 being completed as Lancasters as part of contract No.982866, serial numbers R5768 -R5917, delivered between Mar 41 and Aug 42.

Building a Lanc

As I have said, work at the moment has simply to snip some plastic and do a little test fitting. This time it's quite nice to be furnished with some instructions as I was building blind with the test shot fuse I received in Shizuoka. Unlike that test, this one required me snipping off all of the injection points which double as pin towers, from the circumference of the fuse halves. These are connected to the joint faces, which I prefer, and you'll notice that because of this, there are no pin marks within the fuse halves. Of course, the nose is a separate unit too.Hers's a couple of basic mock-ups of the cockpit area, minus many key details which still need to be installed. This kit does have a serious lack of wiring moulded into the cockpit areas, linking up the various avionics panels. This will need to be added with some lead wire before I can start to add some paint. When complete, things should look quite different.

The bomb bay is around 12 inches long and is constructed as two parts. No other items fit into here apart from the sidewalls. The munitions plug directly into these plates. 18 bombs and 1 cookie.

I also did a little turret work too, and here you can see the rear turret sat in position on the rear fuse. Note the tail spar boxing and the walkway. There will also be internal fuselage doors installed here, which I'll add when the interior is painted.

More soon!

-

9

9

-

-

-

36 minutes ago, Bomber_County said:

Thanks James for very in depth review, as Ernie said a HKM followed by a WnW would be fair.......

That's the plan, but it'll be a year until the release, so I doubt I can do that until then.

-

3

3

-

-

1:32 Avro Lancaster B Mk.I

Hong Kong Models

Well, it’s almost here. After a few short (some would say long!) years of delay, the gargantuan Hong Kong Models’ 1/32 Avro Lancaster B Mk.I is soon to hit the shops, and is in final production as I write this. In a few weeks, the decals will be printed, as will the instruction manual and glossy box with its artwork by Piotr Forkasiewicz. There’s no doubt that this will be an impressive product, and certainly one that will make many a heavy-bomber fan very pleased indeed. HK’s kit has 817 parts, a wingspan of 972mm and a length of 664mm, so you will need some decent place to display it when completed. The wings have been designed to detach in the same way as the B-17, with a slide and lock mechanism, and looking at the instructions, and parts, it does look like you may be able to also detach the substantial tail and fin assemblies. The final model will also come with three schemes, one of which is S-Sugar (PO-S) which adorns the box art. Stencil decals will also be supplied.

My test sample is by no means the final version. A small number of other modifications have already been applied since mine was pulled from the tooling, including an improved wing-locking system via tweaking the wing tools. Arriving by DHL Express from HK, the kit you see here arrived in a plain card box with all parts bound in a many layers of bubble-wrap. However, the clear fuselage/nose parts were actually ready in their heat-sealed packets, and these will be included in the Limited-Edition release. At this point, I expect that the standard grey parts will also be included with this Limited-Edition. The clear parts are also covered in a peelable protective film to lessen the chance of any scuffing on that crystal clear and shiny surface. A relatively small quantity of Limited-Edition kits will be released, and I imagine that a fair few of these will have been sold on kit pre-order.

HK’s kit has FIFTY-ONE (fifty-five for Limited Edition) sprues, a number of which are interconnected on my sample, and may or may not be on the final production release. A number of these aren’t sprues in the most literal sense, but are themselves large, single pieces, such as the fuselage, nose and wings. Two standard clear sprues are included, and everything else is moulded in light grey styrene. The fuselage is split at a joint just inboard of the wing leading edge, as per the actual aircraft, which was sort of built in modules. As for the wings, these are moulded as a single piece, so no need to glue upper and lower halves together. This is produced in the same way as the Mosquito’s innovative single-piece wing. Wingtips are separate items, and these are again moulded as single-piece, hollow parts. Note the openings for the engine nacelle modules to be installed. The latter can be more or less completed and then plugged into the wing, complete with undercarriage for the inboard nacelles.

Whilst it was an original intention to depict oil-canning on the exterior surfaces, HK has decided not to take that approach, and have stuck to their fine panel lines and rivets finish as per today’s standard. The WNW kit will have the quilted appearance on their release which is scheduled for late next year. Internally, the Lanc’s fuse has a complete set of formers and stringers moulded in situ, with no pesky ejector pin marks that need removing. Instead, a series of tabs will need to be cut from the perimeter of these large parts, and a couple from selected windows. Fit of these large parts is excellent, and I can testify to the fit quality of the cockpit too as I built an early test shot just after Japan’s Shizuoka show.

Internally, detail is excellent, with a fully fitted-out cockpit, radio operator, engineer, bomb aimer stations, as well as the infamous main spar which proved such an obstacle to crews which had to abandon their damaged aircraft. Ammunition containers, feed belts, doors to access rear turret, main hydraulics tank, flap jack, flare tube, turret hydraulic pressure recuperators, and even the Elsan toilet for those awkward in-flight moments! As you will imagine, the interior is spread around a number of sprues, and the completed model should look quite amazing. Note that the kit will come with some photo-etch, including such things as the seatbelts, but this test shot doesn’t have that.

Those turrets are also nicely detailed within, and the joint lines on the forward and mid-upper follow a natural frame line. The rear turret glazing is moulded as a single piece item, and all turrets can be positioned/moved when installed. Barrels in this kit are moulded from styrene and the use of slide moulding has created hollow muzzles. Cooling slots are micely depicted. I do know that Master Model will produce a set of barrels specifically for this model. A small sprue contains the mid-upper fairing, and also a blanking plate, but the latter isn’t for use with this release. Another key external part that isn’t scheduled for use with this kit is the bulbous H2S housing that sits under the belly. So, it’s obvious that HKM has plans for the Lanc, as alluded to on the box art (Avro Lancaster Series).

Four detailed engines are included in this kit, plus their respective oil tanks, mounts and firewalls. A little extra lead plumbing and wiring, and these will look very nice indeed. Of course, the intake radiators are included, with their very fine textured finish. Looking at the engine nacelles, HK do seem to have got the shapes correct after a failed few first attempts, so kudos to them for persevering with that. The nacelles, undercarriage and engine installations can be completed as separate units and then installed later. The appearance of the gaping mouth of the intake looks correct, and of course, the engine panels can be posed off the model to reveal the workmanship within. Exhausts are separately moulded stubs with semi-hollow, detailed ends, thanks to slide-mould technology. You will notice that both paddle and needle type prop blades are included, and both look slated for use with this release.

The flying surfaces of the Lanc are pretty large. To strengthen the tail areas, the inside of the parts have a series of ribs that will stop any accidental compression from cracking the seams, and also provide more basic rigidity. Elevators and rudders are moulded separately and can be positioned.

A large bomber needs a substantial payload, and this is supplied by means of 5 sprues of bombs and two which contain parts for the cookie. Plenty of construction work here to fit out the working face of the Lanc, but construction is very simple here. These are moulded with their plungers in situ, as well as fins, and you just need to add the ring to the fins. The instructions show the bomb bay doors and actuators being fitted at fuselage completion, which would be correct as the wings are separate modules which will install later.

Clear parts are exceptional, with well-defined framing and no distortion, visually. Blisters are supplied to fit the main canopy sides, and the forward side canopy windows are separate too. Note that two different bomb aimer blisters are included in my sample, with only one for use with this specific release. I don’t know whether these extra unused parts will be supplied in the general release.

My sincere thanks to HK Models for sending out this test shot for this article, and to build for the Military Illustrated Modeller magazine. In the meantime, check out the Facebook page for building the 1:32 Avro Lancaster, here: https://www.facebook.com/groups/LancAssemblyLine/

-

12

12

-

-

Not at all. Ours will be in the next day or so.

-

2

2

-

-

HKM Lanc sample here. Photos this weekend.

-

3

3

-

-

There's a slight chance it will be here today, but failing that, possibly Monday. It's out for delivery now with DHL, but I can't update my Safe Place option for delivery.

-

1

1

-

-

Holy crap! Now I LIKE that! Makes me want to get adventurous with resin myself (if only my mag deadlines allowed)

-

4

4

-

-

I should have the HK test shot this week, and I'm already slightly damp in anticipation.

-

9

9

-

-

I should have the HKM test kit here this coming week, so I'll post some pics of the parts and some build stuff too.

Also can't wait to see the WNW iteration of this too.

Plenty of room for two manufacturers to release a Lanc.

-

6

6

-

-

1:24 Istanbul Diorama

OcCre

Catalogue # 53010D

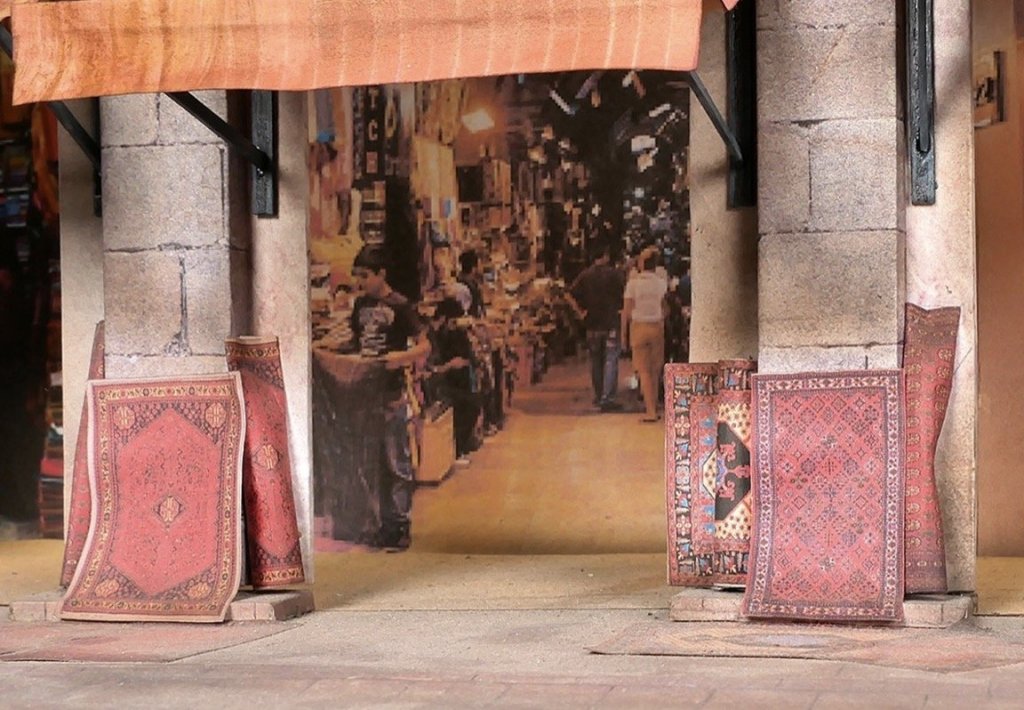

Available from OcCre for €60,95If you’ve recently taken a look at our Istanbul tram review, you might like this particular review article. Yes, of course you can display your tram on a shelf, or in a cabinet, but what about outside Istanbul’s Grand Bazaar? That’s exactly what this new product from OcCre allows us to do, and with relative ease of construction. This is what OcCre have as their website product description:

“The diorama is a representation of the entrance to the Grand Bazaar of Istanbul, one of the largest in the world.

Located inside the old “walled city", on the European side of Istanbul, between Nuruosmaniye, Mercan and Beyazıt, with more than 58 covered streets and 4,000 shops or stalls, every day the bazaar attracts between 250,000 and 400,000 visitors.

The bazaar offers a wide range of products, in particular jewellers, precious metal workers, spice shops and carpet shops. The stalls tend to be grouped together by type, following the tradition of the ancient guilds. The bazaar includes two Bedestens, or domed stone-built structures, which are used for the storage of merchandise. The first of these was built in 1464, by order of Mehmet II, although it then had to be mostly rebuilt in 1864, following the earthquake.

This fabulous diorama combines perfectly with the tram of Istanbul, joining the nostalgic line of Taksim-Tunnel with the Grand Bazaar, in an effort to group two large emblems of the city of Istanbul.”

The kit

The Istanbul diorama is packaged into quite a plain, shallow corrugated cardboard box, with a colour product label attached. There is also a reasonable amount of weight here too, so you know there’s plenty of building material afoot. Upon opening the box, it ca be seen that the multitude of sheet material is wrapped in a heat-sealed sleeve that needs to be cut away. As the sheets in here are various sizes, and the internal box has no compartmentalisation, this is a good way of ensuring that damage risk is minimised. There are also a number of printed sheets which are rolled up, some strip timber and brass wire. A catalogue and sheet pointing to the instructions, are also included. More on the latter in a moment.The numerous sheets are made from MDF and are very neatly laser-cut. You will note how some of the parts have dovetail connections too. In essence, the entire diorama is built up from a series of wall panels that have the Islamic arch shapes that attach to them to create a 3D relief, and this is sat upon a base which is built from sections, to incorporate the ruts along which the tram lines would run. Oddly enough, there is no actual brass section strip to recreate the tram line itself, but instead, timber strip, painted silver, it what’s prescribed. Using some metal strip could be a nice enhancement, but you would need to purchase that yourself, measured against the OcCre tram wheels for best fit.

The idea behind this diorama is that anyone can typically build it, simply out of the box contents. To decorate the walls and floors etc. a series of colour-printed textures are provided, on A4 sheets. These include stone, marble and parquet styles, and these need to be cut out to suit the various structures, and then glued into position with a glue stick, for example. Using wet glues may cause the sheets to ripple and not adhere as flat as they should, although the instructions do actually show brushed PVA as being the glue of choice. Sheets of paper are also supplied to simulate the Bazaar interior, with crowds of people and stalls etc.

When it comes to depicting the exterior details, more printed sheets are supplied, with such things as Turkish rugs, flags etc, and these can be draped over the display stands that sit outside the various stalls on the exterior of the Bazaar. These stalls also have printed awnings to shelter them from the Turkish sun.

To recreate the road itself, then a series of strip card is supplied. This needs to be cut into brick-sized sections, and then plastered over the road in a staggered manner. You can of course then paint and infill between them and add some airbrushed staining to weather things realistically.

Brass wire is supplied for all manner of things, such as the random-looking electrical cables that run along the outside walls.

OcCre supply no instructions for this kit. Instead, they provide an online build guide which is very comprehensive, showing everything right down to measuring out specific dimensions for everything. This multi-part guide is excellent, with the facility to be able to download each part as a PDF. To check out the guide, head to this link: http://www.occremania.com/diorama-de-istanbul-parte-8-2/

Conclusion

Dioramas aren’t usually my thing, but this looks very tempting, just to see if I can make a reasonable attempt at it and add some airbrush work to make it look a little more lived in. There’s certainly a nice quantity of building material here, and all nicely produced. Recreating the street surface will also be quite absorbing, as well as those kerb stones that are cut from the thick strip timber.My sincere thanks to OcCre for providing the review sample seen here. To purchase directly, click the link at the top of the article.

-

3

3

-

-

That is very cool! Loving the fabric finish.

You are my hero.

-

2

2

-

-

1:24 Istanbul tram

OcCre

Catalogue # 53010

Available from OcCre for €96,45Istanbul, the former capital of the Ottoman Empire, once had a large tramway network on both the Asian and the European sides. It first started as a horse tram in 1860 and was gradually converted to an electric tram system starting in 1912. Many additional routes were added to the tram system, in progressive stages over time. The network reached its most widespread extent in 1956 with 108 million passengers being carried by 270 tram-cars, on 56 lines. However reflecting developments in many cities around the world during the 1960s, the tram service began to be closed down in 1956 and was completely stopped in 1966.

The Authority thought to re-introduce heritage trams in Istanbul using the same type of rolling stock which was running in European part until 1962, and in the Asian part until 1966. The original Istanbul tram network was almost completely destroyed, including depots, termini, electric power stations, etc., except for some of the rolling stock which had been preserved in transport museums. Using old photographs, people's memories, and other sources, some rolling stock was built for the European side resembling pre-1962 European-side tram stock, including the size, shape, interior, colour scheme etc. The prototypes had originally been built in 1915. Around 1990, the Istiklal Caddesi became a pedestrian zone, and the tram was restored and revived in 1990, in the form of the Taksim-Tünel Nostalgia Tramway. After a 24-year absence, trams returned to Istanbul. The length of the line is 1.64 kilometres (1.02 mi) and there are 5 stops.

The Istanbul nostalgic tramways are two heritage tramlines in the city of Istanbul, Turkey. The city has two completely separate heritage tram systems, one on the European side (the Taksim-Tünel Nostalgia Tramway, aka. T2 line), the other on the Asian side (T3 line, aka. the Kadıköy-Moda Nostalgia Tramway).

The kit

OcCre’s new Istanbul tram kit replicates one of those heritage trams mentioned in the passage above, and is packed into a slender, standard OcCre box, as per our Terror articlethat we published recently. A colour-printed wraparound label is affixed to this with tape, and a cut-out in the lid is designed to display the plastic tray of components within. Lifting the lid and removing the inserted component tray, we come to the main box and here you slice a few tape tags to open up the contents.

All the timber parts are bundled with two sheets of photo-etch parts and are securely held together with a shrink wrap covering. This compact method of packaging ensures zero damage and all parts are pristine. Now we cut away the cellophane…

This sheet of parts, all cleanly laser-cut, concerns the construction of the tram seating. Each seat is comprised of four parts, varying slightly, dependant on where in the tram it is installed. Note that no parts are engraved with numbers. Instead, you will need to refer to the printed parts plan that is a part of the assembly manual. Timber quality here is high, and all parts are only held in situ with small, easily cut tags.

We now have an MDF sheet included. This one contains a number of parts for which removal of wood grain would have been a PITA, so this is a nice move. The largest part is the tram floor, with various slots and connecting tabs, roof side supports, roof end frames and roof support frames etc.

Our next two plywood sheets are identical, containing frames, cabin ends and internal frameworks, more seat parts, door parts, bulkheads, etc. Each sheet contains over 30 parts, again, all cleanly cut in high-grade ply. Laser scorching is very low, and very localised, and char clean-up should be nice and easy.

The next two sheets are also identical to each other, but instead of being produced from ply, these are also supplied as MDF. This is actually quite a savvy move as I mentioned, as a good number of these will go into building exterior areas of the tram, and of course, there will be no wood grain to remove. Here you can see the slab sides for the tram, more roof frames, boarding platform and chassis frames etc.

A nice thick bundle of various size timber strip stock is included and bundled together with elastic bands. This material will form areas such as internal framing and the planked roof etc. Quality is very good, with only a little wispy material needing to be removed from some of the strip.

That’s the last of the timber areas in this kit, as we now look at the two photo-etch sheets included here. The first one is made from brass, and includes the instantly obvious shutter gates, tram destination sign brackets, external window frame corner trims, etc. Etch quality is superb, with the removal tags being thin and narrow.

The second PE sheet appears to be manufactured from some sort of nickel-alloy, and parts here include the boarding step housings, electric roof sheathing, cabin parts, ventilators, external footplates, and also hand rail mounting points.

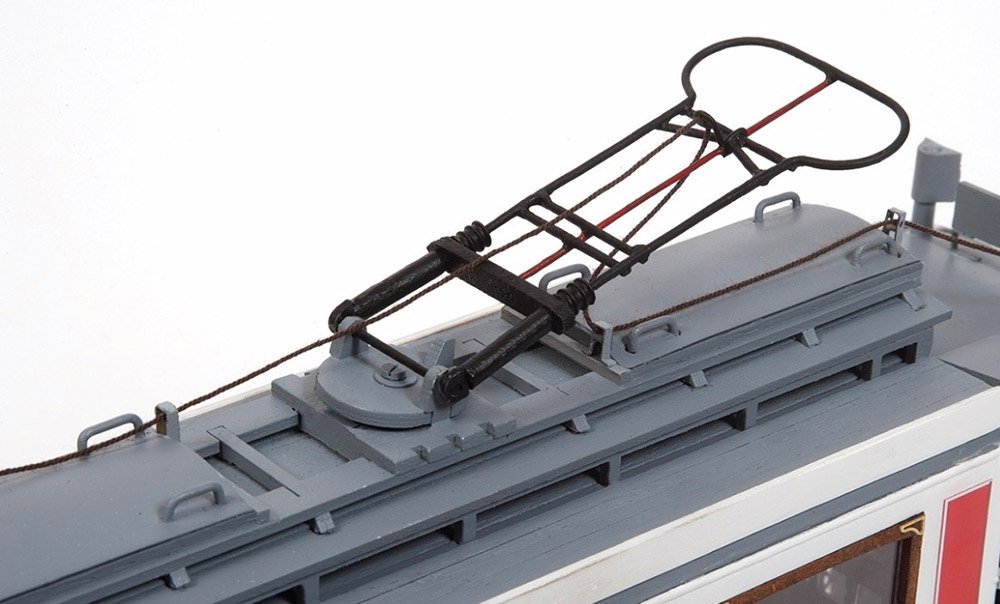

A number of lengths of thick brass wire are included for fashioning all manner of items, such as the trolley pole that catches the overhead electrical lines. Some of these items will need straight edges, so you’ll need to be careful when it comes to ensuring you straighten the wire suitably. I do think that some of these wire items will really lend themselves to being soldered, so if you are capable of that, it’s time to ready the hot iron!

I admit that I didn’t really know how the exterior livery was going to be approached on this model, such as paint, decal etc., but OcCre have in fact included a nice, glossy sheet of self-adhesive panel stickers that should adhere nicely to the smooth MDF surfaces. These have the livery and text already in situ. You will need extreme care in applying these to ensure they line up perfectly, as I don’t know just how sticky they are. Printing quality is excellent, and this really will create the appearance of the tram you see in the photo at the start of this article.

For the windows, a sheet of acetate is included, and for the internal ceiling, another printed sheet is included. This needs to be glued to the internal roof framework before fitting the various ceiling lights and ventilators etc. I do suggest you don’t use any glue which is too wet and would damage the thin paper sheet. Look at using a quality glue-stick instead.

Now we can take a look at that neat plastic tray of components that we can see through the box lid. This is split into twelve compartments, with each holding either a singular type of item, or multiples of different elements. Many of the parts in here are made from cast white metal, such as leaf-spring suspension, interior lights, dampers, cabin components, wheels, couplings, lights, grab-rails etc. There are a small number of turned brass parts and screws in here too, as well as brass eyelets, washers, and a spool of rigging cord to simulate the electricity cable for the trolley pole. There is a small ply sheet too, with just four small parts for an external roof ventilation opening.

As with the previous OcCre kit we looked at, the instructions for this release are all driven by clear colour photos of each stage, showing actual construction of the prototype model. This series of colour, foldedr A3 sheets goes through the building process in a clear and organised way. It’s also worth noting that the parts themselves are added to the mix in a sequential way, meaning it’s easy to trace where in construction a particular element is required. All stock timber sizes are also shown in dimensional form too, to ensure you use the correct material in the appropriate area.

A set of written instructions is also included, referring to the specific photos.

Conclusion

This is certainly an unusual and well-executed little project from OcCre. There’s quite a lot of construction to be had here in both frame and PE, with a more than generous number of extra fittings thrown into the mix. A thoroughly detailed and nicely designed model of a famous heritage tram, and one that I image will be addictive to build. Just as well there’s a whole fleet of world heritage trams to choose from! Maybe we’ll look at a couple more soon.

My sincere thanks to OcCre for the review sample seen here. To purchase directly, click the link at the top of this article.

-

1

1

-

-

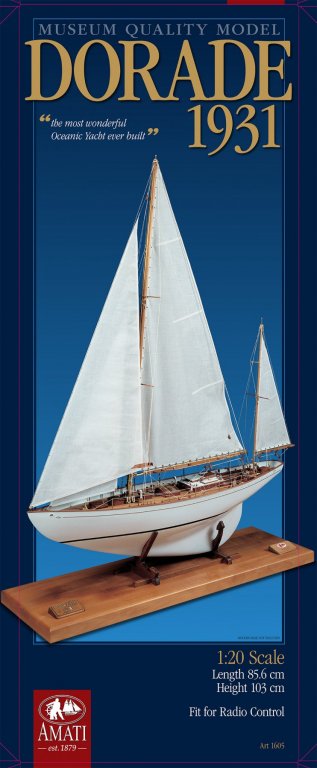

1:20 Dorade – 1931

Amati

Catalogue # 1605

Available from Cornwall Model Boats for £274.00Dorade is a yacht designed in 1929 by Olin Stephens of Sparkman & Stephens and built 1929–1930 by the Minneford Yacht Yard in City Island, New York. She went on to place 2nd in the Bermuda Race later that year. The crew for its first race received the All-Amateur Crew Prize. However, it would be a win in the Transatlantic Race that would bring the boat its name. She completed a race that takes an estimated 3–4 weeks in just 17 days, earning her crew a parade upon the ship's return and a reception for Olin Stephens hosted by the mayor of New York. Olin Stephens, the designer, was skipper through 1932 when he handed the boat to his brother, Rod Stephens. Led by Rod, Dorade sailed to victory in the 1932 Bermuda Race. From Bermuda, Dorade sailed back to Norway, down to Cowes, England, and finally back to America after winning the Fastnet Race. The victory of the 1932 Fastnet Race was of substantial significance given the unusually severe weather, several ships feared missing as well as one recorded drowning among the events that unfolded.

Dorade was completely restored in 1997 at the shipyard of Argentario, in Porto Santo Stefano, Italy. In 2013, Dorade took first place (after applying her handicap) in the Trans-Pacific race that she had won in 1936.

Edit courtesy of WikipediaFor further information on Dorade, check out this excellent page at Dorade.org

The kit

The size of this box (and it’s huge!) certainly belies the weight of it. You’d expect something as heavy as the Vanguard that we looked at a couple of months ago, but that’s certainly not the case at all. The reason for this will be seen in a moment. The box itself is beautifully presented with a super-glossy lid depicting a finished Dorade model, and of course in a portrait format due to the shape of the vessel. The model itself, at 1:20 scale, has given measurements of 85.6cm long, and 103 cm tall. More images of the completed vessel adorn the sides of the box. Now, lifting that lid reveals an open top lower box, unlike the complete and enclosed boxes of other large Amati kits I’ve looked at. Immediately, your eyes are drawn to the reason why this box is relatively light, and that is the inclusion of a complete ABS hull, and hence the reason why this model is stated as being suitable for RC conversion, although the modeller will have to fathom that themselves, as no instructions are given for that particular path. Internally, the box has a number of card inserts to stop the various contents from jangling around loose. It’s only the components tray itself that seems to be a little freer to move, but thankfully, mine hadn’t spilled open or become dislodged.

That ABS hull is very nicely moulded, is fairly thin, and super-light in weight. It has a glossy external finish and will just need some buffing and polishing to remove some very minor surface abrasions. The upper edge will need the fuzziness removed from, but again, this is something that’s very east to do, and not a reflection of the quality, which really is excellent.

First, we take a look at the thick, clear sleeve and the paper contents within. Quite a few Amati releases have a glossy instruction manual, and this has one too, well…at least the cover is glossy, with Italian text giving a short history of the vessel. Inside, the instructions are given in line drawing format, with shading for clarity. All stages have a reference number which can be cross-checked with the written assembly instructions. For these, a glossy Italian manual is provided, with standard A4 sheets provided for both the French and English versions. Going back to the main illustrative instructions, there is some annotation given in all three set languages also. Parts are also clearly identified, whether they be wooden, or one of the many fittings that are supplied. Please note that the timber parts themselves aren’t actually numbered, and you will need to refer to the component identification plan sheet. Construction tips are also given, such as how to mark the waterline.

As for the fittings etc., these can be identified against a comprehensive parts list that is provided in each language, which gives the part number, name, and specific number of included components. I suggest that each packet of components be put in a zip-lock wallet with the kit identifying code written on, to make it easy to locate the parts needed during construction.

FOUR large plan sheets are included in this release, printed on relatively thin paper. The first three sheets provide large scale drawings of the Bessel, from profiles, to upper elevations and sectional material, plus those all-important fitting positions etc. Annotation on the main plans appears to be in Italian, but the illustrations are clear to see, so for a competent modeller, there shouldn’t be any problems encountered. If the worst comes to worst, just use an online translator tool.

The last of the large plan sheets is the parts guide for the wooden sheets, with all parts being easily identified against the instruction booklet. I’m sure I once read that the Dorade kit provided no parts reference for things such as the internal hull framework etc. and that everything was in Italian. Well, if that was the case, then it certainly isn’t now. Remember that companies like Amati revise their kits from time to time, in instructions as well as parts, so maybe that referred to an old issue.

A sandwich of timber is now provided as two long plywood sheets are taped together, with the thin ply deck hiding between them. These main sheets are the thickest timber components in the box and provide the modeller with the various internal hull frames and bulkheads, as well as the parts that make up stand (note that no main plinth is supplied, as shown on the box lid). All parts are cleanly laser-cut with very small tags to cut through to remove them from their sheets.

The deck is a full-length piece of thin ply with mast holes in situ, and the rear panel for lower deck access, just needing removal.

As this is a stylish sail yacht, you need some decent sail material, and a packet of this is included here. You’ll need to cut and stitch these yourself as per plan.

Another thick, clear sleeve contains more timber components, plus a number of other items. One of the timber sheets is a smaller, thin ply sheet with parts associated with the various deck structures, to name but a few. Cutting is again nice and clean, and timber quality is excellent. Parts here are for the various stringers, cockpit sides and edges, funnel flange and deckhouse roof etc.

Two thicker walnut sheets include parts for the rudder, gunwales, belaying pin rack, ventilator tops, skylights, doors, winch steps. Mizzen mast coaming and crosstrees, plus other coamings and side elements. As a number of these parts will be varnished and the wood generally seen, you will need to remove any charring from the laser cutting.

One packet contains some good quality acetate for the various deck structure windows, and also a piece of what appears to be a glossy dark green card. I can’t identify that as of yet.

Timber strip quality is high and also cleanly cut. This first bundle, held by a thread and paper wrap, is for the deck planking. Remember, no hull planking here! This creamy coloured material will need to have a nice deck caulk effect set between them.

Another bundle of timber includes circular and semi-circular dowel lengths, and more strip timber in Ramin and walnut.

Several lengths of brass section strip are included, as is a length of thick copper rod.

Amati has included a reasonably sized sheet of brass photo etch. This really must be the shiniest, most polished PE that I’ve ever seen. Totally mirror-like in quality. Here you will find parts that include mast collars, shelves, trolleys, flanges, portholes, jib brackets, sheave boxes, rails, and turnbuckle and ventilator parts, again, to name but a few. Production quality is first rate, with narrow, thin tags holding the components securely until you need to remove them. A separate, smaller piece of PE contains the external and internal hawseholes.

Lastly, we take a look at the plastic tray of components. This tray is a typical Amati storage box in vac-form plastic, with a clear lid. This is compartmentalised to accommodate the numerous packets of fittings within. Dorade’s fitting tray is certainly weighty, with NINETEEN packets of fittings, nails, decals and rigging cord. Fittings include cleats, portholes, winches, eyebolts, ventilators, boom parrels, turnbuckles, snaphooks, rings, pulleys, sheaves and side lights. Where those parts are cast, the finish is very good, with just a buffing needed before priming.

Conclusion

If you want a project that is a little different from the norm, then Dorade me be just what you are after. With the hull just requiring some remedial finishing before use, plus cutting out the scuppers, you should also find that it’s a relatively quick project that will take a few months instead of running into years. Dorade is a beautiful yacht, and Amati have very much caught her lines here. There is of course a little jigging around between the parts plan, materials and the instructions, and of course with any model this size, you’ll need a reasonable working space, plus some intermediate skills when it comes to tackling the various task required. For the price, she’s also a very attractive subject and will doubtless be a real centrepiece when on display. Quality is typically Amati, and I’m sure you’ll really like this one!My sincere thanks to Amati for the review sample seen here. To purchase, click the link at the top of this article.

-

3

3

-

-

1:32 Arado Ar 234B-2/S3

Fly Model

Catalogue # 32025

Available from Fly Model for £70.90 (at time of writing)The Arado Ar 234 was the world's first, purpose designed and built jet bomber. Its high ceiling capability also saw it operate mainly as a photo reconnaissance aircraft. Lack of room within the fuselage saw bomb pylons being fitted to the underside of the engine nacelles. The dual Jumo 004 engines and operational ceiling saw the type operate with almost total impunity over the UK in the latter stages of the war. It has the distinction of being the last Luftwaffe type to have flown over Britain during the war. Whilst the Ar 234 only entered service in the latter part of 1944, its design requirement was implemented in 1940; around the time that the Battle of Britain had ceased. Unlike many aircraft of the time, the Ar 234 was quite smooth and streamlined in overall appearance, and had its wing mounted to the shoulder of the fuselage, with a Jumo 004 under each wing. The pilot sat in an extensively glazed cockpit which formed the nose of the aircraft.

Problems in the design and manufacture of the jet engines saw the project stall until 1943, and by now, the tide of the war was turning against the Germans. Making its first powered flight in mid-1943, the performance of the Arado was exemplary, despite falling short of the RLM's requirement for overall speed. The original design saw the Ar 234 take off on a detachable trolley and return to earth on a landing skid. Changes in the design saw the Ar 234 being fitted with an undercarriage which fully retracted into its fuselage. Numerous other design changes were tested, such as the use of four BMW 003 engines in both separate and duel nacelle layouts, and also the two-man night-fighter, which saw the rear fuselage being taken over with a radio operator's cockpit. Cannon was also fitted to a pod which was slung underneath the fuselage. That specific type is the subject of this review. By the war's end, 210 Ar 234 had been built, of all types, and despite numerous technical issues with the machine, the type was liked by its pilots, and proved manoeuvrable enough to even perform aerobatics! A key drawback of the type was the long take off distances, which led to accidents. To counter this, RATO (Rocket Assisted Take Off) units were suspended under each wing. When jettisoned, these fell back to earth on a parachute which was fitted to their nose.

The kit

Has it really been four years since we first say the initial Ar 234 kits from Fly? I built one of the initial releases for Military Illustrated Modeller, and I have to say that it was one of the most pleasurable projects that I’d tackled in a while. So, it was very pleasing to see that Fly has slightly altered these kits in terms of parts and/or decals and given us two new releases with some really nice and unusual schemes. At the moment, if you want to build an Ar 234 in injection plastic, Fly’s kits are the only game in town. There is a superb and accurate resin kit in 1:32, from MDC and mastered by Radu Brinzan. If whole resin kits frighten you, or you just don't like the medium, then Fly Model's latest releases will positively delight you. In this review, we’ll take a look at the Arado Ar 234B-2/S3.

The first thing that might surprise you is how small the boxes are for these multimedia releases. Fly Model produce low pressure, injection moulded kits which incorporate resin and photo etch parts. I'm no stranger to their releases, and I have built their Bachem Ba 348V 'Natter', Hurricane, Westland Wessex and original Arado kit, two of which have featured on the cover of Military Illustrated Modeller. Fly's packaging and artwork is very attractive, even if the box itself isn't a super-glossy production as we see from the likes of Hasegawa etc. A rather nice image of a an Ar 234 being tailed at duck by a P-51D, adorns the lid, and the under-belly bombload is clearly seen, as are the engine-mounted bomb racks.

Inside the box, there are FOUR tan/fawn coloured styrene sprues which have been packaged into a single re-sealable sleeve, including three bags of resin parts too, and an individually sleeved clear sprue. Unlike the other Ar 234 releases, this has a separately packed part which extends the length of the forward fuselage. Plastic in low-pressure injection kits does tend to be a little softer, of course, and my sample has some very minor scuffing that will need to be buffed out. Also included is a comprehensive sheet of decals, a photo etch fret, some wire and cord, and an A5 instruction booklet. The sprues themselves don't have ID letters, with the part numbers starting with the fuselage sprue, and running in sequence to the last sprue. For the sake of this review, we'll still call them 'A' and 'B' etc. There has been discussion on the release of the original Fly kits with regards to accuracy, and what some perceive as issues, but if you want to read those, feel free to Google it. For me personally, I don't know enough about the Arado to comment on some details. Having already built the original release, all I can say is it looks just like the Ar 234 I know and was great fun to build. I'll leave any accuracy issues for another man on another day.

Sprue A

For the first time, we seen the unmistakable lines of the Ar 234. Whilst the fuselage is conventionally split into halves, the forward nose section is a single, separate piece. This will allow the cockpit to be built and installed before the nose is married to the fuselage. I give Fly real credit for just refined the surface detail is on this. Panel lines are extremely subtle. You feel that they will only just hold a wash. They are also evenly scribed, with perhaps the slightest loss of detail around the underside seam. This is no issue as I'd only have to replace the detail once I've sanded back the joints. As is correct, the forward main gear door is moulded closed, with only the strut door of course being an open area. A little flash will need to be removed, but nothing major. External surface detail is quite sparse, which is probably correct for the type, but there are a number of neatly engraved access ports, and some fastener detail. The rudder is also separately moulded, and the wing slots into a quite thin slot on the fuselage shoulder. As with the rest of this kit, there are no locating pins between parts. This is very common for short-run kits.

The RATO units are included here, moulded as halves, and with some pretty neat filler port and strap detail. These parts are for the actual RATO unit, and not the accompanying parachute. The latter are included as resin parts.

Other parts on this sprue include the two-part nose-wheel, main gear doors, and also the bomb pylon mounting units which fit to the underside of the engine nacelles. I do think the wheel looks rather simplistic and will need a little work to bring it to scratch. The inside of the gear doors are also devoid of any real detail, and could use a little work.

Sprue B

Both of the wing undersides are moulded here, with integral ailerons and landing flaps. I would quite like to have at least the landing flaps as separate parts, but again, this is usually the approach with short-run kits, and it's only a minor criticism. Surface detail really is excellent, with numerous, fine panel lines and access ports. Also scribed are the external lines which indicate where the Jumo 004 nacelles will be fitted, minimising guesswork.

This aircraft, whilst capable of carrying a bomb, doesn’t have one supplied. That is available separately, and I’ll post info on that as soon as I have one here. However, the pylons are occupied with fuel drop tanks, should you wish to fit them. The tanks are moulded as halves and look every bit as good as those you'll see in conventional, contemporary kits. Detail includes hard mounting points and fillers. The main wheels are also far prettier than the nose wheel, with excellent internal and external hub detail which looks very convincing. Fine raised lines radiate from the centre of the tyre, outwards. Again, this looks very good. Wheels, however, aren't weighted, so you'll need to solve that issue yourselves.

Other parts on this sprue include the recessed, belly weapons mount which is superbly detailed, engine nacelle breather inlets, and also the rudder and elevator counter-masses.

Sprue C

Engine nacelles are supplied in halves, and into these will go a resin intake, and a resin exhaust which will be supplemented by the variable position 'onion' that controls thrust. Fine panel lines and fasteners adorn the exterior of the nacelles, and internally, a small raised step helps to locate the internal resin parts.

A two-piece rudder is included, which is the only real part of the exterior to exhibit any rivet lines.

Until now, we haven't seen any cockpit parts, but that is because the main parts are produced in resin. However, there are still a number of injection moulded parts on this sprue. One of these is the instrument panel. My only qualm with this is that it has moulded instrument face detail. In actuality, that detail is very good, if not better than many contemporary kits, but decals are also supplied for the faces, and raised detail makes them a little tricky to successfully attach. I do think the panel itself is good enough not to use the decals, but should you wish to, you could easily scratch-build a new panel. Having a glazed nose, the rear of this panel is very visible, and Fly include a series of resin instrument bodies that will be seen here. Just wire them up!

For me, the cockpit is one of the really attractive areas of the Arado and would be either a deal maker or breaker. Fortunately, Fly have done an amazing job of this key area, and the side consoles are testimony to that. Detail is excellent, and there is plenty of it too. This will also be enhanced further with photo-etch levers etc. These are very busy areas of the pit! Numerous other cockpit details can be found here, including the rudder pedal slide mount rods, highly detailed control stick, and other ancillary instrumentation panels. Two internal side wall parts are also included. The undercarriage parts are to be found here. Main strut gear detail is quite simple, but certainly sharp, and the various struts and forks are certainly more than passable. Other parts include the fuel tank/bomb pylons, Funkgerat loop base, and nose gear doors. Again, I'd suggest a little extra detail work within the doors.

Sprue D

Here we have the upper wing panels, exhibiting the same refined levels of detail as the rest of the airframe. When I built my original Arado, I used the MDC flush rivet tool on the airframe, and I think the result really did transform things, especially in the bare wing panel areas.

Those Jumo 004 'onion' parts are found here, moulded as halves. These are simple looking by design. I can tell you that if you have a spare Jumo sprue from a Trump Me 262, the engine will fit nicely in the nacelles.

Stabilisers are moulded with integral elevators. This is a bit of a shame if you wished to pose them. I may do that for my own build. Detail is supplied by means of finely engraved panel lines.

Sprue E

Again, clear parts are another area where low-pressure kit manufacturers can, and often do, fall flat with. I have always found the clear parts in Fly kits to be very good, and these are no exception. This clear sprue contains ELEVEN parts, but only eight will be used. The forward canopy comprises two of these. Framing is very good, and so is clarity. I used to recommend dipping canopies in Klear to help enhance clarity, and level any imperfections. With this canopy, Klear (or similar) could be doubly important because the black framing with the bolts is supplied as a series of decal strips, in the same manner as the MDC kit. You may want to paint the frames and then attach the decals, but that would be pointless. You can simply apply them directly to the Klear'ed part.

Ok, I do have another criticism here. With such a detailed cockpit, it would have made sense to mould the entrance hatch as a separate part, allowing it to be posed in an open position. Fly haven't done this, so when I built mine, I drilled this out and make a new door so that I could pose it open, allowing for a cockpit view.

Plastic Summary

I don't really have any complaints about the styrene in this kit. There is a little flash and a few seams to remove, but there are no visible sink marks or other production defects. There is a lack of locating pin presence, but as I have said, this is very typical of kits of this type.Resin

There are THREE bags of resin parts here, providing the real detail in this kit. All resin parts are produced by Artillery and are cast in medium grey resin. Artillery do some great work, and these parts are no exception. Casting is flawless, and mastering is very detailed. Let's take a closer look, bag per bag.The first zip-lock wallet contains a god few chunks of resin. I say chunks because there are some quite hefty parts here. One of the largest parts forms the rear cockpit bulkhead with its associated detail (wiring looms, tanks, and junction boxes), including an integral nose wheel bay which internally forms the section to which the pilot's seat fits. The wheel bay is chock full of pipework too, and I'm sure will present more than just a little difficulty in access for painting. A large casting block exists to the rear, but this should be kept in place due to it housing the wheel bay.

Port and starboard main gear bays are excellent. The box structures feature the various frames and constructional elements, as well as the row of access plates, numerous wiring looms and gear actuator jacks. Test fitting these within the fuselage shows that there's nothing to worry about. The location of them is pretty obvious. A little thin CA to initially fit, followed by a bead of epoxy, should do the trick nicely. A single casting block contains the bomb sight and pilot seat. Fantastic detail throughout, as you can see from my photo.

The other parts in this bag are the front and rear Jumo engine faces, with superbly sharp fan faces, and also the parachute packs for the RATO pods. These have been made to look like folded fabric, and really are very good. You'll need to employ some craft shading and highlights to compliment the detail. A casting block will need to be removed from the rear.

The second resin bag contains more casting blocks which contain around another FIFTY parts. These include the numerous instrument bodies for the rear of the IP, oleo scissors, various cockpit parts (battery, map case, fuse board and oxygen regulator etc.), undercarriage parts etc. Some parts here have broken from the casting blocks, but the parts themselves are thankfully intact.

One more bag contains a single part. This is to extend the length of the fuselage slightly, just to the rear of the cockpit. I’m thinking that the one scheme that uses this part, was perhaps assigned to an experimental unit, as the nacelle undersides are painted in RLM04 Yellow.

Photo-etch

This etch fret contains one full sets of seatbelts, and whilst I admit that these will be very useable, I think I would opt for the more photo-realistic HGW option. This fret also contains the forward edging for the cockpit consoles, console levers, rudder pedals etc. Other parts include control surface actuators and the dipole array for the fuselage spine. The PE is superbly made, with small tags holding all parts in place.

Errata

A small bag contains two pieces of cord of different diameters, and also a short length of rigid wire. I'm sure the cord is partly for the cockpit, with a length being used for the drag chute cable. I'm unsure what the wire is actually for, but it can be used to pin some key parts of resin/plastic to other main components, giving a little extra rigidity.

Decals

A single decal sheet is included, which contains both national markings, codes and serials and also a full suite of stencils and dashed walkway lines. As I have mentioned, the canopy framing lines are supplied as strips which you'll need to cut to length. Cockpit instrument decals are also supplied, but I used the superior Airscale decals on my previous build. Whereas the original release had awkward multipart swastikas, this new kit has the complete symbol printed, so it’ll be far easier to apply.

Decals are thinly printed and contain minimal carrier film. The colours are solid and authentic, and registration is perfect. You could wish for no more.

A glossy A4 sheet depicts the three schemes, and these are:

- Arado Ar 234B-2, flown by Major Hans-Georg Bätcher, Commander of III./KG 76, January 1945

- Arado Ar 234B-2, flown by Obstl. Robert Kowalewski during attackon Remagen Bridge by Gefechtsverband KG 76, March 1945

- Arado Ar 234B-2/S3, W.Nr.140103

Instructions

This is a 20-page A5 manual, printed in black and white, with shaded line drawings for stage illustration. All looks very easy to follow, and very comprehensive. You will need to study things closely to decipher what is plastic, etch or resin. Colour information is basic, so please check your references. I still think the manual is pretty clear about construction, and you should find no problem with it. Of course, the scheme illustrations are in colour.

Conclusion

It’s great to see this model released back to the market in this incarnation, with the subtle change and new schemes. I can only speak from personal experience when I say that it builds up beautifully into a quite a large and convincing replica of this dedicated jet-bomber. This is one where you can really go to town with extra details, such as riveting etc. but the resin parts really do help to create a great kit, straight from the box, with a gorgeous cockpit area too. Go treat yourself. I guarantee you’ll enjoy this project!My sincere thanks to Fly Model for the review sample. To purchase directly, click the link at the top of this article.

-

8

8

-

It seems like an age since I actually did a build here, and at least one that wasn't sidelined because my schedules changed.

In that light, here's one that HAS to see completion as it's for the WNW stall at Telford this year.

This is the forthcoming Albatros D.V in one of Richthofen's schemes. There are two rail options here as you can see, and I think I'll add the red area to mix things up a little further. I've started cutting some plastic, so I'll pst some photos as soon as I can.

-

4

4

-

-

47 minutes ago, nichenson said:

Do normal American blades fit in that? Looks like the holes may be off.

I honestly can't say as I'm European and not seen US blades. They do sell blades separately too.

-

24 minutes ago, karimb said:

Thanks Jim for taking the time to write a review. i bought a similar cutting jig few years back from another manufacturer but i keep noticing the cuts have started to become a bit oblique where the blade slices, so to say, due to the blade flexing. Those thicker blades do look the part and i am seriously considering the RP one...

thanks again

Karim

If you do, let those guys know you read my article

-

2

2

-

-

-

2 minutes ago, McCoy said:

This one could in fact be the best one on the market thanks to it's sturdiness. I'm extremely tempted to get one for myself.

I've seen decent mitre tools and really cruddy ones. IMHO, this is the best, beyond doubt.

-

2

2

-

-

Cutter/Mitre Tool

RP Toolz

Catalogue # RP-CUTR

Available from RP Toolz for €85,00RP Toolz’ Cutter Tool (or Mitre Tool) isn’t really a new idea. There are of course a few manufacturers out there who produce fairly similar tools, and I used to have one of them myself, so when RP Toolz announced that they were releasing their own, I was pretty keen to see it for myself. A mitre tool is designed so that the modeller can produce mitred plastic junctions of specific angles on strips of either flat styrene or shaped section stock. If you’ve ever tried to make a 90-degree angle frame, you’ll know how difficult it is to get right if you don’t have the correct tools. The Cutter Tool is designed to ease all of your woes.

This tool is packaged into a robust, corrugated box with a colour product label on the lid. You’ll also notice the weight. There’s some heavy metal in here, and some of the best you’ll see from a tool manufacturer. Unlike some contemporaries who may mould their cutters in some form of plastic, this one is precisely CNC-machined from a very hard grade aluminium, which has also been given a tough matte red anodised finish. The box fits the tool almost perfectly, with an insert used to support the cutter arm. A hex key is provided for changing the blade, as is a second blade with a finer cut. The tool is fitted with a 0.3mm thick blade for regular cutting tasks, with a slightly thinner (0.25mm) blade for something a little finer.

The first thing you notice when exploring this tool is that there is no playin any of the parts. That is, there is no looseness or wobble in either the arm pivot or the two adjustable fences. Those fences are also neatly engraved with degree graduations and the base is marked with a reference point too, in order to align the fences. The bottom edge of the fences is also marked, but in centimetres, with ZERO being at the actual cutting point of the blade. With the fences in their neutral position, an end stop can be positioned so you can cut precise and equal straight-edged lengths of strip. This stop can be removed of course so the fences can be adjusted. It can also be switched to the opposite side of the cutter for maximum flexibility. The stop and both fences are tightened using plastic thumbscrews that cover the metal fixing bolt.

Now, a cutting area really needs a cutting mat, and this is what is fitted to this tool. A self-healing and graduated mat, sits flush with the upper surface of the tool, and proved a hard yet non-damaging surface to the cutting blade.

I made a small number of cut tests with this tool and found it both precise and effortless.

Conclusion

RP Toolz’ arsenal of quality modelling tools is certainly expanding, and like those before it, the sheer quality of this really does demand the price asked of it. This is no flimsy or inaccurate tool, but one with which you can work with total precision in producing either angled lengths of styrene, or equal, multiple lengths too. If you like to scratch-build or even just improve on what a kit supplies, then this could well be of interest to you. This is the very best of the mitre cutting tools that I have ever seen, without a doubt.My sincere thanks to RP Toolz for the review sample seen here. To purchase directly, click the link at the top of the article.

-

4

4

-

-

Lancaster B Mk.I, R5868, PO-S (S-Sugar)

in LSM 1/35 and Larger Work In Progress

Posted

And as usual, Airscale will make a full appearance in this one too